Our Technology

BRINGING THE FOREST INTO THE LAB

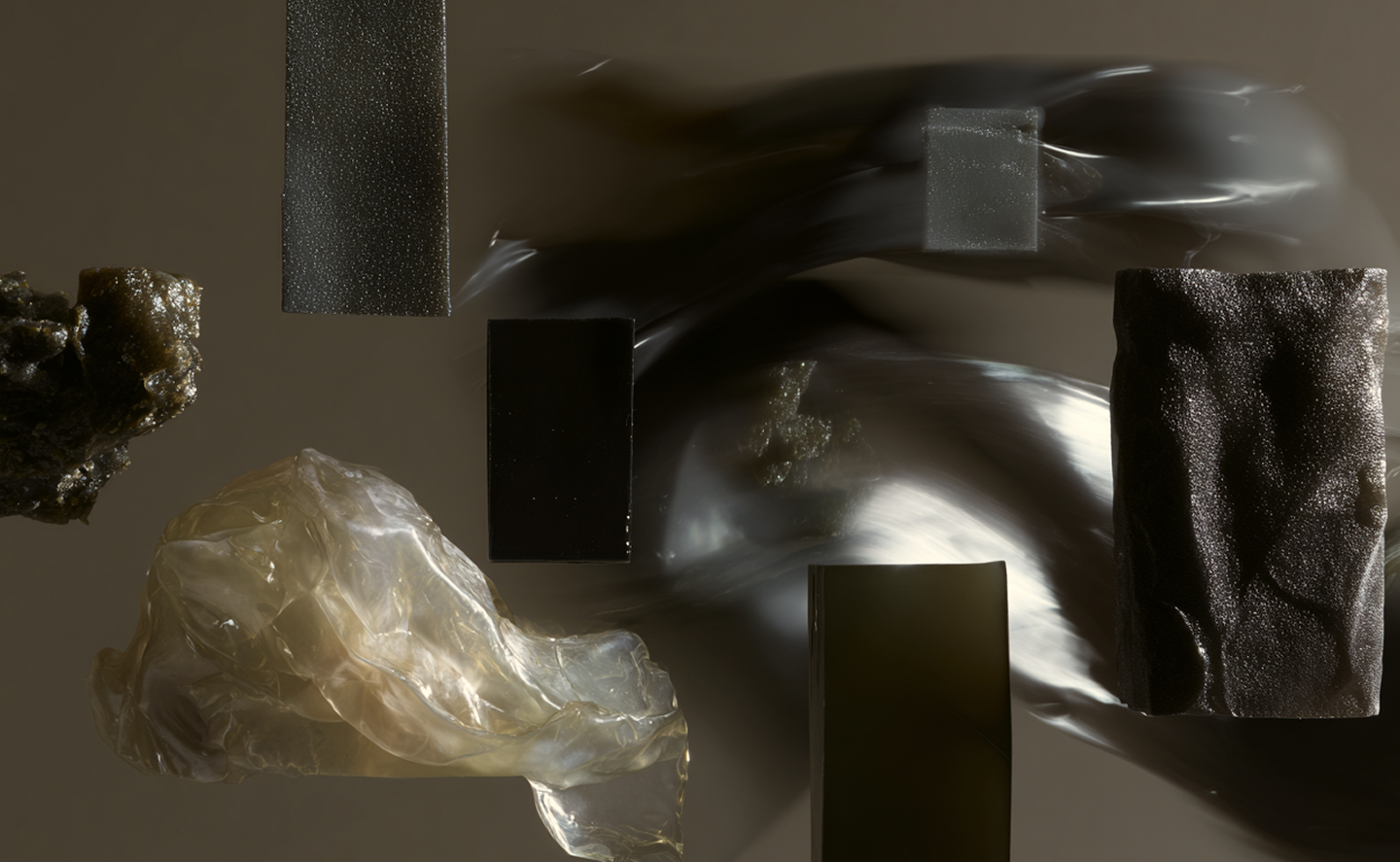

The technology uses birch bark, which has been used by indigenous peoples for thousands of years for shelter, building, transportation, and storage due to its lightweight, flexible, and waterproof properties. Today, birch bark is mostly a residue of the pulp, paper, and plywood industry, primarily serving as fuel.

In 2019, while at the Wallenberg Wood Science Centre, co-founder Dr. Thomas Baumgarten discovered a better use for the bark. He found that birch bark components could be isolated and reassembled to create a novel rubber-like material, now known as Reselo Rubber.

SUBERIN IS WHERE THE FLEXIBILITY IS FOUND.

The isolated building blocks for our Reselo Rubber originate from Suberin, a polyester network of long-chain fatty acids highly abundant in birch bark. This natural polymer forms a hydrophobic barrier in the bark that helps the birch tree control water flow and makes it more resistant to extreme weather and parasites.

FROM NATURE TO INDUSTRY

Thomas' environmental awareness also meant that he designed this process using only benign solvents and relatively mild reaction conditions-our respect for and collaboration with nature can be seen even in the lab.

How is the technology scalable?

Thomas designed an initial isolation process that was simple enough to be readily scalable and resulted in high yields, which made the process commercially attractive. Until this point, commercialising birch bark-derived products had stagnated as this had been too difficult.

WE CONTINUE DEVELOPING OUR MATERIAL

TO PREPARE FOR TOMORROW'S CHALLENGES

Today, our process experts continuously improve our process, making it even safer and more resource-efficient. In addition, we’re working on industrialising the production of Reselo Rubber, which has been greatly supported by public funding from Sweden and the EU.

We collaborate directly with industrial equipment suppliers and research institutes to scale our process. We have already completed pilot trials and are working towards establishing the first Reselo Rubber-producing plant in Northern Europe.

A NATURAL CHOICE FOR

A CHANGING WORLD

Our goal is to generate alternatives to the over 15 million tons of fossil-based synthetic rubbers produced globally every year, and our technology is on track to help us achieve this.

CHECK OUT OUR MATERIAL